World health organization presentation

World health organization presentation

World Health Organization

Published byAshtyn Mullins Modified over 7 years ago

Similar presentations

Presentation on theme: «World Health Organization»— Presentation transcript:

1 World Health Organization

7 April, 2017 International Health Regulations Building international public health security

2 Why revised International Health Regulations?

World Health Organization Why revised International Health Regulations? 7 April, 2017 In today’s world, diseases travel fast and no single country can protect itself on its own. Acknowledging this, the 193 WHO Member States unanimously adopted a new version of the International Health Regulations (IHR). The revised IHR enter into force in June It will now be up to the world to translate the new code of the Regulations into the reality of greater international public health security. Dr Margaret Chan, WHO Director-General

3 Our world is changing as never before

World Health Organization 7 April, 2017 Populations grow, age, and move Diseases travel fast Microbes adapt Chemical, radiation, food risks increase Health security is at stake The unique conditions of the 21st century have amplified the invasive and disruptive power of epidemics and other public health emergencies. The dynamics of disease spread in the world have changed greatly in the last decades. We all are living in a global “village” where diseases can travel at the speed of jetliners on the wings of international travel and trade, and can jump from one continent to another in a matter of hours. This has made all nations vulnerable – not just to invasion of their territories by pathogens, but also to the economic, political and social shocks of public health events elsewhere. They have the power to disrupt the entire global system in ways that cannot be controlled by one nation acting alone. SARS was the first disease of the 21st century to expose the world’s vulnerabilities. It will not be the last. Shared vulnerabilities imply shared responsibilities and create a need for strong collective action to protect lives and livelihoods from disease spread. To address these public health risks, the world’s countries, through WHO, initiated an intensive process to revise the IHR, eventually adopted by the World Health Assembly in May 2005.

5 2003: SARS changes the world

World Health Organization 7 April, 2017 Screening of exit passengers WHO travel recommendations WHO travel recommendations removed 27 March 2 April 25 May 23 June 120000 SARS: an unknown coronavirus 8098 cases 774 deaths 26 countries affected trends in airline passenger movement drop economic loss: US$ 60 billion 100000 80000 Number of passenger 60000 SARS taught us how quickly a new disease can spread along the routes of international air travel. This universal vulnerability creates a need for collective defences and for shared responsibility in making these defences work. SARS finally spurred the energy of world’s States, coordinated by WHO, to strongly take action and strengthen global defences to health threats without boundaries 40000 36 116 20000 14 670 13 May 3/16 3/19 3/22 3/25 3/28 3/31 4/3 4/6 4/9 4/12 4/15 4/18 4/21 4/24 4/27 4/30 5/3 5/6 5/9 5/12 5/15 5/18 5/21 5/24 5/27 5/30 6/2 6/5 6/8 6/11 6/14 6/17

6 H5N1: Avian influenza, a pandemic threat

World Health Organization 7 April, 2017 The greatest threat to international health security would be an influenza pandemic. It has not receded, but early warnings allow the world a chance to prepare. Implementation of the IHR is the chance to prepare

7 World Health Organization

The 58th World Health Assembly adopts the revised International Health Regulations, “IHR” World Health Organization 7 April, 2017

9 World Health Organization

What’s new? World Health Organization 7 April, 2017 From three diseases to all public health threats From preset measures to adapted response From control of borders to, also, containment at source The IHR are innovative because they move from purely a list of diseases to a dynamic process of risk identification, assessment and management they move from a concept of static defence at borders, airports and ports to the concept of early detection, reporting and containment at source they built on the concept that international health security is based on strong national public health infrastructure connected a global alert and response system.

10 All public health threats

World Health Organization All public health threats 7 April, 2017 The revised IHR recognize that international disease threats have increased Scope has been expanded from cholera, plague and yellow fever to all public health emergencies of international concern They include those caused by infectious diseases, chemical agents, radioactive materials and contaminated food

11 World Health Organization

Adapted response World Health Organization 7 April, 2017 International public health security is based on strong national public health infrastructure connected to a global alert and response system. This is at the core of the IHR. SARS taught us how quickly a new disease can spread along the routes of international air travel. This universal vulnerability creates a need for collective defences and for shared responsibility in making these defences work. The containment of SARS was due to unprecedented cooperation between countries which prevented a new disease gaining a foothold in the human population. The IHR build on this and many other efforts to respond to and contain disease threats and will help to ensure that outbreaks and other public health emergencies are detected and investigated more rapidly and that collective international action is taken to support affected a states to contain the disease and apply life saving interventions. GOARN A “strike force” of specialized staff is rapidly deployed for on-the-spot emergency investigations through the Global Outbreak Alert and Response Network (GOARN). It interlinks in real time 120 networks and institutes. For chemical, radiological and food-related incidents GOARN is complemented by WHO Chemical Incidents and Emergencies Network (ChemiNet) Radiation Emergency Medical Preparedness and Assistance Network (REMPAN) International Food Safety Authorities Network (INFOSAN)

12 World Health Organization

Containment at source World Health Organization 7 April, 2017 Rapid response at the source is: the most effective way to secure maximum protection against international spread of diseases key to limiting unnecessary health-based restrictions on trade and travel The extent of international travels is an extraordinary opportunity for disease transmission.

13 World Health Organization

What do the IHR call for? 7 April, 2017 Strengthened national capacity for surveillance and control, including in travel and transport Prevention, alert and response to international public health emergencies Global partnership and international collaboration Rights, obligations and procedures, and progress monitoring

14 Why should countries implement the IHR?

World Health Organization Why should countries implement the IHR? 7 April, 2017 To detect and contain public health threats faster, to contribute to international public health security, and to enjoy the benefits of being a respected partner. Countries will receive: WHO assistance in building core capacities WHO’s guidance during outbreak investigation, risk assessment, and response WHO’s advice and logistical support information gathered by WHO about public health risks worldwide assistance to mobilize funding support

15 The IHR foster global partnership

World Health Organization 7 April, 2017 Other intergovernmental organizations: UN system (e.g. FAO, IAEA, ICAO, IMO) others: regional (e.g. EU, ASEAN), technical (e.g. OIE) Development agencies: governments, banks WHO Collaborating centres Academics & professional associations Industry associations NGOs and Foundations The IHR provide for cooperation between WHO and other competent intergovernmental organizations or international bodies in the implementation of the Regulations. WHO will therefore continue to foster its longstanding working relationships with a number of organizations such as the International Atomic Energy Agency, the International Air Transport Association, the International Civil Aviation Organization, the International Maritime Organization, the World Tourism Organization, Food and Agriculture Organization of the United Nations, the Office International d’Epizooties (World Organisation for Animal Health) and the World Trade Organization. In addition to these specialized organizations, WHO will work with regional economic integration organizations such as the European Union and the Mercado Común del Sur (MERCOSUR) in implementing the Regulations in the countries of their respective regions.

16 Acute public health threats are collectively managed

World Health Organization Acute public health threats are collectively managed 7 April, 2017 The IHR define a risk management process where States Parties work together, coordinated by WHO, to collectively manage acute public health risks. The key functions of this global system, for States and WHO, are to: detect verify assess inform assist Timely and enhanced epidemic intelligence Real-time exchange of situational reports and other data for decision-making Enhanced information management and risk communications Joint risk analysis and decision support Action planning and coordination of response activities Technical partnerships to support international health security.

17 WHO to help countries managing events

World Health Organization WHO to help countries managing events 7 April, 2017 New WHO global Event Management System WHO Regional Alert and Response teams Train countries’ NFPs and WHO contact points for event management Expand GOARN and other specialized and regional support networks Develop new tools and standard operating procedures Carry out IHR exercises WHO wide-exercise tests the global system for international health security On, 15 June 2007, the day of the IHR’s entry into force, WHO will hold the first exercise to test its preparedness to successfully manage and support States during public health emergencies of international concern. As part of WHO’s increased responsibilities under the revised IHR, considerable effort has been made to establish procedures, technological and human resource infrastructures to ensure WHO is ready to receive, analyse and disseminate information and make recommendations for dealing with public health emergencies of international concern. The exercise on 15 June is the first of a series meant to test the mechanisms in place, their compliance with the IHR and opportunities for improvement. It consists of notifying a public health event involving multiple regions. This is an occasion to validate policy direction and coordination, information management and risk assessment capacity as well as the ability to utilize communications methods to report events from the country level through the Regional Offices to Headquarters. Participants will span many levels of WHO across the globe, including selected country office staff, WHO IHR contact points, Regional Directors, Regional Advisors, WHO Emergency and Preparedness and Response group at Headquarters, and the office of the Director-General.

18 As each country builds its capacity, the entire world wins

World Health Organization 7 April, 2017 The greatest assurance of public health security will come when all countries have in place the capacities for effective surveillance and response, for: infectious diseases radiological-related diseases chemical-related diseases food-related diseases Timeline «As soon as possible but no later than five years from entry into force» 2 years (2) + (up to 2) Each country has committed to develop and maintain core public health capacities for surveillance and response. These capacities encompass outbreaks of infectious diseases and diseases of chemical, radiological and food origin. Health services and facilities are also to be developed at important international ports, airports and ground crossings. 15 June 2007 2009 2012 2014 2016 Planning Implementation

19 Countries’ challenges for IHR implementation

World Health Organization Countries’ challenges for IHR implementation 7 April, 2017 Mobilize resources and develop national action plans Strengthen national capacities in alert and response Strengthen capacity at ports, airports, and ground crossings Maintaining strong threat-specific readiness for known diseases/risks Rapidly notify WHO of acute public health risks Sustain international and intersectoral collaboration Monitor progress of IHR implementation

20 What will WHO do under the IHR?

World Health Organization What will WHO do under the IHR? 7 April, 2017 Designate WHO IHR contact points Support States Parties in assessing their public health risks, through the notification, consultation, and verification processes Inform State Parties of relevant international public health risks Recommend adapted public health measures Assist States Parties in their efforts to investigate outbreaks and meet the IHR national requirements for surveillance and response

21 Benefit from IHR implementation

World Health Organization 7 April, 2017 Lives saved Good international image No unilateral travel and trade restrictions Public trust No political and social turmoil The legally binding nature of IHR(2005) does not include an enforcement mechanism per se for the States which fail to comply with its provisions. Nevertheless, the potential consequences of non-compliance, especially in economic terms, are a powerful compliance tool. Being a binding international agreement, the IHR(2005) are associated to greater expectations of compliance by their State Parties through greater expectations of compliance by other parties and concerns about potential retributive measures by other countries in case of non-compliance. Working together with WHO to control a public health event and to communicate accurately any associated to other States or their populations helps to protect against unjustified measures being adopted unilaterally by other States.

Презентация была опубликована 4 года назад пользователемАлександра Викторовна

Похожие презентации

Презентация на тему: » ВОЗ» — Транскрипт:

1 Приготовила : Рыбалко Александра, студентка 209 группы

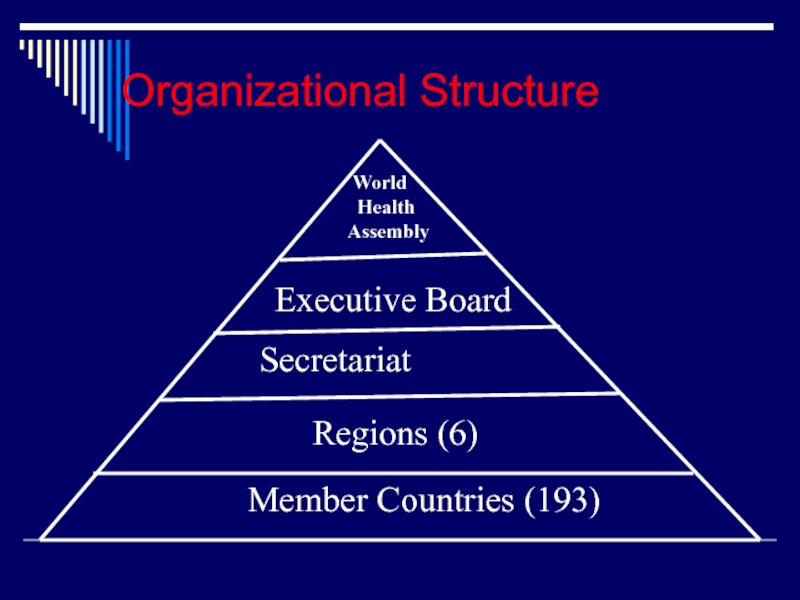

3 Всемирная ассамблея здравоохранения Исполнительный комитет Секретариат

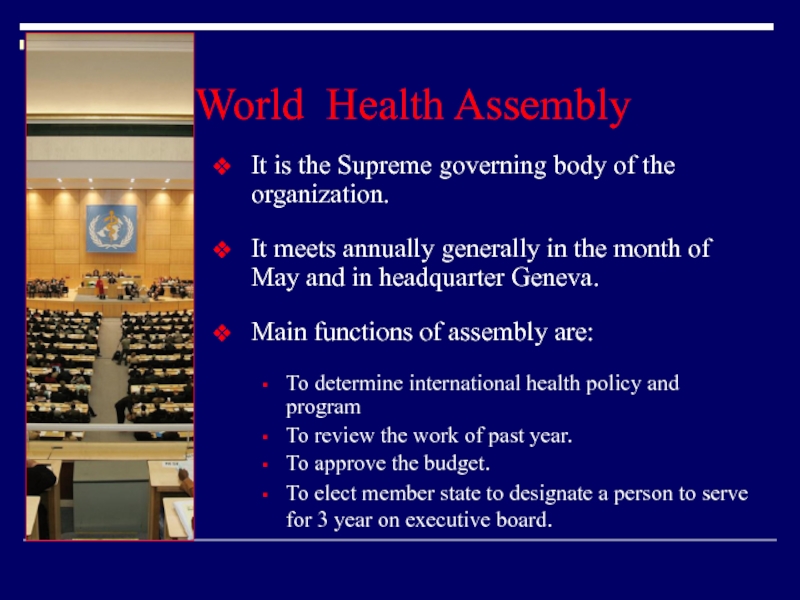

4 Всемирная ассамблея здравоохранения ( англ. World Health Assembly, сокр. Ассамблея здравоохранения ) высший руководящий орган Всемирной организации здравоохранения. Ассамблея здравоохранения собирается на ежегодные сессии, как правило в мае в Женеве во Дворце Наций ООН.

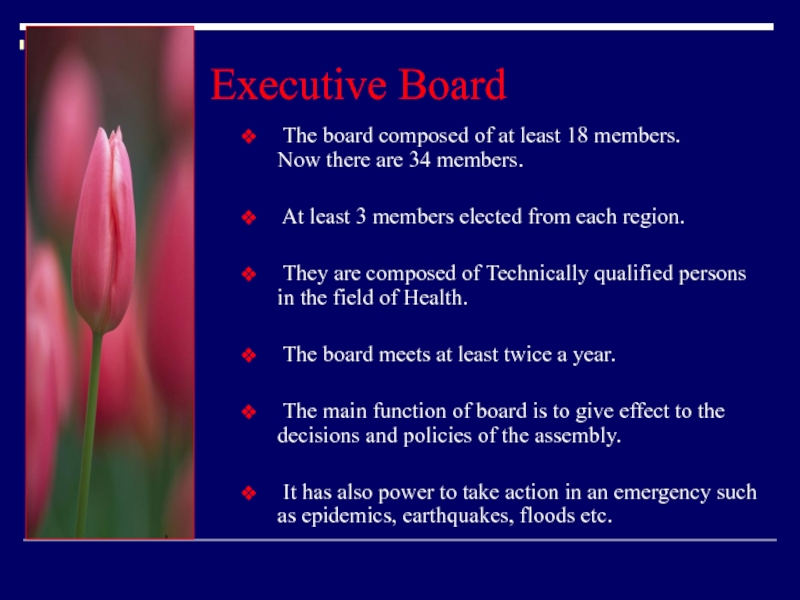

5 Исполнительный Комитет Всемирной Организации Здравоохранения руководящий орган ВОЗ, осуществляет управление организацией в перерывах между сессиями Всемирной ассамблеи здравоохранения. Состоит из 34 членов.

6 предоставление международных рекомендаций в области здравоохранения установление стандартов здравоохранения сотрудничество с правительствами стран в области усиления национальных программ здравоохранения разработка и передача соответствующих технологий, информации и стандартов здравоохранения.

World Health Organization

Published byRosaline Dalton Modified over 7 years ago

Similar presentations

Presentation on theme: «World Health Organization»— Presentation transcript:

2 World Health Organization

Personnel World Health Organization 15 April, 2017 Objectives To review general issues related to personnel To review requirements for key personnel To review the training of personnel To consider some specific issues There are four objectives for this session: 1. We are going to start by looking at the principles and general issues around personnel such as the personnel policies and practices. 2. We will look at the responsibilities of certain key personnel in the organization. 3. We will review continuous training of personnel. 4. We will look at the specific issues that are likely to arise during your inspection visits.

3 World Health Organization

Personnel 15 April, 2017 Principle Establishment and maintenance of satisfactory system of QA, manufacture and control of products and actives rely on people. Must be sufficient qualified personnel to carry out tasks Individual responsibilities must be clearly defined and understood by individuals concerned Written job descriptions All personnel should be aware of the principles of GMP that affect them The principle that companies should apply to their people has a number of key features. The personnel is the most important asset of a company, and the easiest to neglect. The establishment and maintenance of a satisfactory system of quality assurance and GMP relies upon people who develop the system, the people who use the system and the people who examine the system to see if it has worked. People are involved, no matter how automated the process or how capital intensive the operation. The behaviour of the people is fundamental to any system of GMP. Personnel policies must reflect this. In our first group session we will be looking at those policies that encourage compliance with GMP. Sufficient number of staff must be available to carry out the work for which the manufacturer is responsible. These people must have the level of training and experience that will enable them to do their work. The staff must have written job descriptions to ensure that they understand clearly what it is that they have to do, and what they are responsible for. Finally these staff must have a knowledge and understanding of GMP to enable them to carry out their duties in accordance with GMP. Let us now look at these areas in more detail. 9.1

5 World Health Organization

Personnel 15 April, 2017 General (2) All responsible staff should have specific duties recorded in individual written job descriptions Have adequate authority to carry out responsibilities May delegate to designated deputies with qualifications No gaps or unexplained overlaps Organization chart Staff must have a clear job description which tells them and the rest of the company what their role is, what their responsibilities are and what authority they have to carry out their tasks. The company should also have a written organization chart. The combination of organization chart and written job descriptions enables the company to see quickly whether there are any gaps or whether there are any areas of overlap, owing to too many people being involved. The organisation chart should make clear and ensure the independence of QA/QC from production. Personnel involved in QA/QC must have the authority to carry out their responsibilities. This is very easy to say and sometimes not so easy to ensure. Problems can emerge in every size of company, from small private companies to very large multinational enterprises. They arise because of a combination of human interactions, and the pressures placed on people by the business considerations. 9.3

6 Basic Principles of GMP

Organization chart This is NOT what it should look like

7 World Health Organization

Personnel 15 April, 2017 General (3) All personnel should be aware of GMP Must receive training in GMP: initial training continuing training including hygiene standards Motivated to support the establishment maintain high-quality standards All personnel involved with materials and products should receive GMP training. This training should commence upon recruitment and continue throughout employment. The training should be appropriate to their needs and position within the company, and should include training in hygiene standards. Personnel policies should be designed to encourage people to support the development and maintenance of high quality standards in all work performed. 9.4

8 World Health Organization

Personnel 15 April, 2017 General (4) Prevent unauthorized access To production areas Storage areas Quality control Stop personnel who do not work in these areas using them as passageways The company should prevent people who have not been properly trained from entering any production, storage or quality control area without strict supervision. For example: it should not be the case that people from accounts are allowed to walk through the factory to get to the warehouse to pick up or deliver invoices. Access to all other areas of the company should be organized so that no entry to production, storage or laboratory areas is necessary (see Premises). 9.5

9 Basic Principles of GMP

World Health Organization 15 April, 2017 The trainer should explain ways of ensuring access control to areas. Some companies have electronic card systems that allow entry to authorized persons to specific areas, others have a code that has to be entered at the door, etc. Only people authorized to go to areas, should be allowed to enter, wearing appropriate garments. They should have the relevant training before entering the areas. IN some cases, to ensure also better control between different classes of areas, airlocks are used.

10 World Health Organization

Personnel 15 April, 2017 Key Personnel (1) Key personnel (which normally should be full-time) positions include: Authorized person Head of Production Head of Quality Control May delegate functions – not responsibility Heads of Production and Quality Control should be independent of each other We have dealt with the generalities of an organization so far. We shall now deal with the requirements for certain key people in the organization. Who are these key people? The heads of production, quality control, sales and distribution and the authorized person who releases product for sale are all key people. Normally they should all be full-time positions. The heads of production and quality control should not report to one another (although they may both report to a technical director) but may share certain responsibilities. In large organizations, it may be necessary to delegate some of the functions; however, the responsibility cannot be delegated. We will look in a minute at shared responsibilities. Different countries take a different view of reporting relationships. Legislation in each country differs slightly and, of course, local legislation must be followed. The principle is that there must be independence of quality control from production. These key personnel must have the education and experience which is appropriate to their positions. As we mentioned earlier, difficulties can arise when family members who are recruited and who are inexperienced. 9.6

11 World Health Organization

Personnel 15 April, 2017 Key Personnel (2) Should posses appropriate qualifications Scientific education such as: chemistry or biochemistry chemical engineering microbiology pharmaceutical sciences and technology pharmacology and toxicology physiology; or other related science subjects relevant to the responsibilities to be undertaken The WHO GMP text part one, section 9.7 refers to some of the acceptable qualifications of key personnel and it goes into a lot of detail. Key personnel should first of all have the educational background specified by local legislation and with the requirements set out in company policy. This will include a combination of chemistry, biochemistry, chemical engineering, microbiology, pharmaceutical sciences and technology, pharmacology and toxicology, physiology or other related science subjects relevant to the responsibilities to be undertaken. In particular, the GMP text talks about gaining experience not in a haphazard way, but under specific guidance of an expert. This is in order to equip personnel with an ability to take difficult decisions in a professional and scientific way, and to resolve the problems encountered in manufacturing and quality control. It is clear, therefore, that we are talking about professionals who have had a practical as well as an academic training. They should also continue to have training in their area of expertise. There are others who play an important role in the operation of the factory, for example, engineers. Engineers are crucial to the maintenance and operation of the facility and equipment, in particular, for the processes of planned preventative maintenance and validation. 9.7

12 World Health Organization

Personnel 15 April, 2017 Key Personnel (3) Should posses appropriate experience Practical experience Manufacture and quality assurance Preparatory period under professional guidance sometimes needed Education and experience should enable personnel to take difficult decisions in an independent, professional and scientific way resolve the problems encountered in manufacturing and QC Personnel should also posses appropriate experience including practical experience in the manufacture and quality assurance of pharmaceutical products. It is common and recommended, that there should be a preparatory period under professional guidance for new employees. Education and experience should enable personnel to take difficult decisions in an independent, professional and scientific way, and to resolve the problems encountered in manufacturing and QC. 9.7

13 World Health Organization

Personnel 15 April, 2017 Shared Responsibilities (1) Heads of Production and Quality Control may share/jointly exercise some responsibilities relating to quality: authorization of written procedures (SOPs) and other documents, including amendments monitoring and control of manufacturing environment plant hygiene process validation and calibration training, including application and principles of QA approval and monitoring of suppliers and contract acceptors The responsibilities shared by the heads of the production and quality control departments are described in the WHO GMP texts. Clear written job descriptions must be available for these positions, showing where the shared responsibilities are. It is sensible that all procedures and documents used in manufacturing are approved by both the production and quality control departments. It is most important that an effective system of change control is implemented. It is essential that as SOPs are changed, all those who use them are given the latest version. Monitoring of the manufacturing environment is a task to be shared between QA/QC and production. These departments should conduct the monitoring and testing as appropriate, with the results made available to all who need to know. Both production and quality control have a role to play in the development and maintenance of an appropriate factory sanitation and hygiene management system. Both have a major contribution to make in the validation of processes and the calibration of equipment. A comprehensive training programme is required for personnel. The production and quality control department have a role to play in the development of the training programme. The heads of these departments, therefore, have a shared responsibility for the implementation of that programme. Approval of all suppliers and contract manufacturers is also an area of shared responsibility, with each contributing his/her own particular expertise 9.8

14 World Health Organization

Personnel 15 April, 2017 Shared Responsibilities (2) Designation and monitoring of storage conditions for materials and products Performing and evaluating in-process controls Retention of records Monitoring compliance with GMP Inspection, investigation, and taking of samples to monitor factors which may affect quality Responsibility for the designation and monitoring of storage conditions is also shared. Since both have responsibility for the generation of records relevant to batches, then the arrangements for the storage of those records may be a shared responsibility. Alternatively a separate department may be available that manages all aspects of documentation and batch records. Monitoring of compliance with GMP is also a shared responsibility. This has to be correct because the achievement of GMP is everyone’s responsibility. Some aspects of inspection, investigation and sampling may be conducted by people other than QC to monitor factors that affect quality of the products. Sampling should only be done by persons trained in the methods to be used. 9.8

19 World Health Organization

Personnel 15 April, 2017 Authorized person: Responsibilities (1) Compliance with technical and regulatory requirements Approval of the release of finished product for sale Establishment and implementation of quality system Development of quality manual Supervision of self-inspections and quality audits Authorized person: Responsibilities (1) The authorized person is responsible for compliance with technical or regulatory requirements related to the quality of finished products and the approval of the release of the finished product for sale. The authorized person will also be involved in other activities, including the following: (a) implementation (and, when needed, establishment) of the quality system; (b) participation in the development of the company’s quality manual; (c) supervision of the regular internal audits or self-inspections; 9.11

20 World Health Organization

Personnel 15 April, 2017 Authorized person: Responsibilities (2) Oversight of the QC department Participation in external audits and vendor audits Participation in validation programmes May delegate approval of release of product through approved procedure Normally by QA by means of batch review The authorized person will also be involved in other activities, including the following: (d) oversight of the quality control department; (e) participation in external audit (vendor audit); (f) participation in validation programmes. The function of the approval of the release of a finished batch or a product can be delegated to a designated person with appropriate qualifications and experience who will release the product in accordance with an approved procedure. This is normally done by quality assurance by means of batch review. 9.12, 9.13

23 World Health Organization

Personnel 15 April, 2017 Training (1) Training, in accordance with a written, approved programme all personnel whose duties take them into production areas; or into control laboratories; and for others whose activities could affect the quality of the product including technical, maintenance and cleaning personnel Induction and continuing training on theory and practice of GMP and their duties training records should be kept practical effectiveness checked training before undertaking any new task Inspectors should check the company procedure, training materials and records on training provided. Training should be given in accordance with a written, approved programme to all personnel whose duties take them into production areas; or into control laboratories; and for others whose activities could affect the quality of the product including technical, maintenance and cleaning personnel) On induction and continuing; 1. Each company should establish a written training programme. New employees understand what is expected of them and the risks to patients and consumers if the products they make do not conform to requirements. This initial training must be given to all employees who have a direct impact on product quality. The training programme may consist of at least two parts. The first will be a general programme that all employees should receive which explains GMP and the importance of GMP to the company. There may well be a second programme, explaining the specific issues about the individual’s department. 2. There should be a written re-training programme for all employees to ensure that their skills are continually brought up to date and that they are introduced to changes in practice as these develop. 3. As employees go through their training, records should be kept of the training received and performance against tests. People have to realise that good performance is required otherwise retraining will be required. 4. All areas of GMP relevant to the individual must be covered. 5. Training records must be kept to ensure that as employees move around the company, they are not required to carry out work for which they have not been trained. 10.1, 10.2

25 World Health Organization

Personnel 15 April, 2017 Visitors or Untrained Personnel Preferable not to enter production and control areas. If this is unavoidable then: They must be given information in advance, particularly about personal hygiene protective clothing requirements Must be accompanied and closely supervised at all times One of the questions that you should raise in all companies is how they handle visitors. The answer should be that their presence should be treated as a potential risk to the product and, therefore, steps should be taken to ensure that they cannot cause any hazard to product quality. Ideally, the company will do this by factory design that ensures that visitors cannot gain access to areas in operation. This is usually difficult and so it is necessary to give visitors a full briefing and to provide them with full protective clothing and give them strict instructions about where they may stand. For visitors there can be no exceptions to the rule of the wearing of appropriate clothing to protect the product. A word at this stage about visits by the owners of the business. This may be a difficult area because owners may feel that if the company is theirs they may do what they want, when they want. Somehow they have to understand that their investment is at risk if they do not behave as necessary. (Use flipchart again to record comments from the audience). 10.5

26 World Health Organization

Personnel 15 April, 2017 Consultants and contract staff Should be qualified for the services provided Training records maintained Records should prove qualifications A manufacturer may use the services of a consultant and contract staff. The company has to ensure that these people are qualified for the services provided. It may be useful for you to review also the training records maintained for contract staff. Some companies use contract workers for some activities including packaging of products. They should have been properly trained in GMP, QA and the relevant procedures and processes that they are responsible for. Records should prove persons’ qualifications 10.6

27 World Health Organization

Personnel World Health Organization 15 April, 2017 Group Session What do you think will be the key personnel issues to arise during an inspection? What sort of responses do you think you should give to these issues when they become apparent? Having heard the presentation on personnel, use what you know to develop thoughts on the likely issues regarding the organization of personnel that you will meet during inspections in your countries. More personal issues arising during an inspection are dealt with in the modules on GMP inspections. Once you have drawn up a list, develop the responses that you feel would be appropriate in those circumstances.

28 World Health Organization

Personnel World Health Organization 15 April, 2017 Possible Issues – I Limited number of staff Inadequate qualifications Inadequate experience Owner interferes in quality decisions Lack of means to develop training materials In a company the issues will be around a lack of skills and resources to comply with all the requirements of GMP: Limited staff numbers may mean that people are under pressure to perform. They may be trying to do too much. There may be a lack of deputies during times of illness or holidays. Recruited staff may have inadequate qualifications. Recruited staff may have inadequate experience or experience in an inappropriate area. Sometimes the owner recruits relatives who are inadequately qualified or experienced. The owner may interfere with quality decisions, particularly if orders are required urgently or are very valuable. Senior staff may have difficulty in combating this, since it may cost them their jobs. Smaller companies may have no means to develop training materials to educate their staff in the requirements of GMP. They do not become members of the local manufacturers’ association because of cost. They do not then have access to training programmes that are available through the association.

29 World Health Organization

Personnel World Health Organization 15 April, 2017 Possible Issues – II Company procedures take precedence over local legislation Unclear organization diagram Staff movement Inadequate training records Illness Subsidiaries of multinational companies may claim that company procedures or standards take precedence over local legislation. If this is claimed, it will be most unusual since all multinationals require local companies to conform first to local legislation. It will be worth exploring with the company what benefits are obtained by not conforming to local legislation. Large organizations often move people around through promotion, training, recruitment or relocation. In so doing they can lose sight of the requirements of GMP. Managers can be promoted into positions for which they are not qualified or experienced. Companies may not keep adequate training records even though people are apparently undergoing training. As with small companies, large companies may have personnel policies that penalize people. The problem is that if people are not going to be paid when sick or injured, they may work on under circumstances that create a risk to the product. What happens when they have an open wound, for example?

World Health Organization

Published byLisa Randall Modified over 7 years ago

Similar presentations

Presentation on theme: «World Health Organization»— Presentation transcript:

1 World Health Organization

19 April, 2017 Supplementary Training Modules on Good Manufacturing Practice Validation In this supplementary training module, we will be looking at the recommendations by WHO, on Validation and qualification. The module consists of 7 parts: Part 1. General overview on qualification and validation Part 2. Qualification of HVAC and water systems Part 3. Cleaning validation Part 4. Analytical method validation Part 5. Computerized system validation Part 6. Qualification of systems and equipment Part 7. Non sterile product process validation Each part deals with a specific topic, and each part can be presented in about one to one and a half hours time. Presenters should know the topics and add practical examples to the texts taken from the WHO guideline. WHO Technical Report Series, No. 937, Annex 4.

2 World Health Organization

19 April, 2017 Validation Part 1. General overview on qualification and validation Part 2. Qualification of HVAC and water systems Part 3. Cleaning validation Part 4. Analytical method validation Part 5. Computerized system validation Part 6. Qualification of systems and equipment Part 7. Non sterile product process validation

3 World Health Organization

19 April, 2017 Supplementary Training Modules on Good Manufacturing Practice Non sterile product process validation Part 7 WHO Technical Report Series, No. 937, Annex 4. Appendix 7.

4 World Health Organization

Validation World Health Organization 19 April, 2017 Objectives To discuss non-sterile process validation, focusing on: General recommendations Prospective validation Concurrent validation Retrospective validation Revalidation Change control Objectives To discuss Non-sterile process validation, focusing on: General recommendations Prospective validation Concurrent validation Retrospective validation Revalidation Change control

5 World Health Organization

Validation 19 April, 2017 Principle Documented evidence: Process is capable of reliably and repeatedly rendering a product of the required quality Planning, organizing and performing process validation Process validation protocols Data collected and reviewed against predetermined acceptance criteria – recorded in validation report Principle Documented evidence: Process is capable of reliably and repeatedly rendering a product of the required quality. Planning, organizing and performing process validation Process validation protocols Data collected and reviewed against predetermined acceptance criteria – recorded in validation reports. 1.1 – 1.2

6 World Health Organization

Validation 19 April, 2017 Scope General aspects of process validation for the manufacture of non-sterile finished products Should cover at least the critical steps and parameters, i.e. those that may have an impact on the quality of the product 2. Scope 2.1 These guidelines describe the general aspects of process validation for the manufacture of non-sterile fi nished products. 2.2 Normally process validation should cover at least the critical steps and parameters (e.g. those that may have an impact on the quality of the product) in the process of manufacturing a pharmaceutical product.S 2.1 – 2.2

8 World Health Organization

Validation 19 April, 2017 Prospective validation Critical factors or parameters possibly affecting finished product quality to be identified during product development Breakdown of production process into individual steps Evaluate each step Determine the criticality of these factors through a “worst-case” challenge where possible 4. Prospective validation 4.1 Critical factors or parameters that may affect the quality of the finished product should be identified during product development. To achieve this, the production process should be broken down into individual steps, and each step should be evaluated (e.g. on the basis of experience or theoretical considerations). 4.2 The criticality of these factors should be determined through a “worst-case” challenge where possible. 4.1 – 4.2

9 World Health Organization

Validation 19 April, 2017 (continued) Prospective validation protocol should include: description of the process and of the experiment equipment and/or facilities to be used including measuring or recording equipment (and its calibration status) variables to be monitored details of the samples to be taken product performance characteristics/attributes to be monitored, together with the test methods acceptable limits and time schedules personnel responsibilities details of methods for recording and evaluating results, including statistical analysis 4.3 Prospective validation should be done in accordance with a validation protocol. The protocol should include: — a description of the process; — a description of the experiment; — details of the equipment and/or facilities to be used (including measuring or recording equipment) together with its calibration status; — the variables to be monitored; — the samples to be taken — where, when, how, how many and how much (sample size); — the product performance characteristics/attributes to be monitored, together with the test methods; — the acceptable limits; — time schedules; — personnel responsibilities; and — details of methods for recording and evaluating results, including statistical analysis. 4.3

10 World Health Organization

Validation 19 April, 2017 Approach: Equipment, production environment and analytical testing methods – already fully validated e.g. during installation qualification and operational qualification Appropriately trained personnel and batch manufacturing documentation prepared after these critical parameters have been identified, and machine settings, component specifications and environmental conditions have been determined and specified 4.4 All equipment, the production environment and analytical testing methods to be used should have been fully validated (e.g. during installation qualification and operational qualification). 4.5 Personnel participating in the validation work should have been appropriately trained. 4.6 Batch manufacturing documentation to be used should be prepared after these critical parameters of the process have been identified, and machine settings, component specifications and environmental conditions have been determined and specified. 4.7 A number of batches of the final product should then be produced. The number of batches produced in this validation exercise should be sufficient to allow the normal extent of variation and trends to be established and to provide sufficient data for evaluation.S 4.4 – 4.6

11 World Health Organization

Validation 19 April, 2017 Approach (2) A number of batches of the final product should then be produced What number of batches? sufficient to allow the normal extent of variation and trends to be established and to provide sufficient data for evaluation Data within the finally agreed parameters from at least three consecutive batches, giving product of the desired quality may be considered acceptable 4.7 A number of batches of the final product should then be produced. The number of batches produced in this validation exercise should be sufficient to allow the normal extent of variation and trends to be established and to provide sufficient data for evaluation.S 4.7 – 4.8

12 World Health Organization

Validation 19 April, 2017 Approach (3) Same size batches Full-scale production batch size If not possible – reduced batch size considered Validity of assumptions made should be demonstrated when full-scale production starts Extensive testing at various stages in the manufacturing process – including on the final product and its package 4.9 The batches should be of the same size, and should be the same as the batch size intended in full-scale production. Where this is not possible, the reduced batch size should be considered in the design of the protocol and when full-scale production starts, the validity of any assumptions made should be demonstrated. 4.10 Extensive testing should be performed on the product at various stages during the manufacturing process of the batches, including on the final product and its package. 4.9 – 4.10

13 World Health Organization

Validation World Health Organization 19 April, 2017 Setting Limits: may include Marketing authorization limits stability specifications Release specification Validation limits Setting limits: Marketing authorization limits: usually the national compendia limits or those agreed at the time of product registration. The product must meet these at any time that it is on the market and within its expiry date. Stability specifications: The specification minimally needed to maintain required potency over the shelf life of the product, based on stability study data. Release specification: the product must meet at the time of release and in order to allow for any changes (super-potency, sub-potency, dissolution, disintegration, etc) over shelf life of product. This is the simplest criteria for setting validation acceptance testing, but will not necessarily include process capability. In the development of acceptance criteria, all three of the above specification areas must be taken into consideration, including an analysis of data gathered during the initial development and stability work. In most cases, this data will be limited but will give enough information on test and process variability to allow for some guidance. The most important thing to remember is to keep the statistics simple. Validation acceptance criteria may be tighter than, or equal to the release limits, which may be tighter than, or equal to the compendial limits. Marketing authorization limits based on stability specifications Batch release limits Validation limits

15 World Health Organization

Validation 19 April, 2017 Determining critical control points A useful strategy to determine which steps to study intensively, is to “flow chart” the process and conduct a hazard analysis of critical control points. Critical control points indicate critical processing steps. It is necessary to note how often critical control points come at the end stages as the value-adding process proceeds. The flow chart above shows a tablet granulation process where Step XVI and XVIII have been identified as a critical control point. Blend uniformity and cleaning validation has to be performed at step XVI, and during actual manufacture, a reconciliation of the actual yield against the expected yield must be performed before the tablet compression step. (The trainer should explain that this diagram is incomplete, as there are other IQ, OQ, PQ requirements, steps, etc. to be included The slide provides an example only.)

17 World Health Organization

19 April, 2017 Validation Solid dose mixing (2) In situ analysis Methods of analysis Statistical analysis inter-batch intra-batch within-sample-site Solid dose mixing: (Contd) There are now manyin situ spectroscopic approaches, such as infrared (IR), near-infrared (NIR), and Raman spectroscopy, which are fast, accurate and easily performed. Probes may be placed directly into the mixing vessel or be positioned at windows along the walls of the vessels, allowing for real-time, uninterrupted homogeneity measurements. Remember uniformity or homogeneity are being considered, not a determination of the active. Although the best marker is the active (must be the active for low dose and potent product), the marker can be chosen if it is representative of the blend. The methods of analysis for these samples of the blend are extracted and assayed by UV or HPLC, or similar validated test method. Note that non-specific methods are satisfactory – which is a big difference from e.g. stability studies. The actual spectra (from, for example, near-Infrared) and methods of calculating the homogeneity of the actives should be subject to statistical analysis. The within-sample-site variability must also be acceptable for low dilution powders, such as micro-dose tablets or capsules. This can usually be demonstrated on just the first batch, not for each of the three batches. It is a “minivalidation” of the sampling thief and sampling method used.

21 World Health Organization

Validation 19 April, 2017 Results in the report that includes, e.g. process description including details of critical steps detailed summary of the results obtained from in-process and final testing, including data from failed tests raw data or reference to these any work done in addition to that specified in the protocol any deviations from the protocol with an explanation a review and comparison of the results with those expected formal acceptance or rejection of the work by the team or persons designated as being responsible for the validation, after completion of any corrective action or repeated work 4.11 The results should be documented in the validation report. As a minimum, the report should include: • a description of the process: batch/packaging document, including details of critical steps; • a detailed summary of the results obtained from in-process and final testing, including data from failed tests. When raw data are not included, reference should be made to the sources used and where it can be found; • any work done in addition to that specified in the protocol, or any deviations from the protocol should be formally noted along with an explanation; • a review and comparison of the results with those expected; and • formal acceptance or rejection of the work by the team or persons designated as being responsible for the validation, after completion of any corrective action or repeated work. 4.11

22 World Health Organization

Validation 19 April, 2017 Conclusion and recommendation: Made on the basis of the results obtained Incorporated into the batch manufacturing and batch packaging documents and/or standard operating procedures (SOPs) for routine use Limits and frequencies of testing and monitoring should be specified. Actions in case of OOL If validation batches are to be sold or supplied: manufactured under GMP conditions Compliance with the marketing authorization 4.12 A conclusion and recommendation should be made on the extent of monitoring and the in-process controls necessary for routine production, on the basis of the results obtained. 4.13 The conclusion and recommendation should be incorporated into the batch manufacturing and batch packaging documents and/or standard operating procedures (SOPs) for routine use. Limits and frequencies of testing and monitoring should be specified. Actions to be taken in the event of the limits being exceeded should be specified. 4.14 Batches manufactured as part of the validation exercise, and intended to be sold or supplied, should have been manufactured under conditions that comply fully with the requirements of good manufacturing practice and the marketing authorization (where applicable). 4.12. – 4.14.

23 World Health Organization

Validation 19 April, 2017 Concurrent validation May be appropriate to validate a process during routine production Can you give any examples? Decision made by appropriately authorized personnel Premises and equipment previously qualified Done as per validation protocol; and results documented in the validation report Concurrent validation 5.1 In certain cases, it may be appropriate to validate a process during routine production, e.g. where the product is a different strength of a previously validated product, a different tablet shape or where the process is well understood. 5.2 The decision to carry out concurrent validation should be made by appropriately authorized personnel. 5.3 It is essential that the premises and equipment to be used during concurrent validation have been previously qualified. 5.4 Prospective validation should be done in accordance with a validation protocol. 5.5 The results should be documented in the validation report. 5.1 – 5.5

24 World Health Organization

Validation 19 April, 2017 Retrospective validation Comprehensive review of historical data Requires a protocol and a report with a conclusion and a recommendation Not the preferred method of validation, and used in exceptional cases only: e.g. for well-established processes Inappropriate in case of changes (e.g. equipment) Retrospective validation 6.1 Retrospective validation is based on a comprehensive review of historical data to provide the necessary documentary evidence that the process is doing what it is believed to do. This type of validation also requires the preparation of a protocol, the reporting of the results of the data review, a conclusion and a recommendation. 6.2 Retrospective validation is not the preferred method of validation and should be used in exceptional cases only. It is acceptable only for well-established processes and will be inappropriate where there have been changes in the composition of the product, operating procedures or equipment. 6.1 – 6.2

25 World Health Organization

Validation 19 April, 2017 Retrospective validation (2) Sufficient data to be reviewed to provide a statistically significant conclusion Satisfactory results of retrospective validation only serve as an indication that the process does not need to be subjected to validation in the immediate future 6.3 Sufficient data should be reviewed to provide a statistically significant conclusion. 6.4 When the results of retrospective validation are considered satisfactory, this should serve only as an indication that the process does not need to be subjected to validation in the immediate future. 6.3 – 6.4

26 World Health Organization

Validation 19 April, 2017 Revalidation Standard processes (with conventional equipment) data review similar to retrospective validation Points to be considered: the occurrence of any changes in the master formula, methods, starting material manufacturer, equipment and/or instruments calibrations and preventive maintenance carried out standard operating procedures (SOPs) cleaning and hygiene programme 7. Revalidation Note: see main text on “Validation”. The need for periodic revalidation of non-sterile processes is considered to be a lower priority than for sterile processes. 7.1 In the case of standard processes using conventional equipment, a data review similar to that which would be required for retrospective validation may provide an adequate assurance that the process continues to be under control. The following points should also be considered: — the occurrence of any changes in the master formula, methods, starting material manufacturer, equipment and/or instruments; — equipment calibrations and preventive maintenance carried out; — standard operating procedures (SOPs); and — cleaning and hygiene programme. 7.1

27 World Health Organization

Validation 19 April, 2017 Change control In case of changes, consider the change and its impact on the process validation Examples of changes (requiring revalidation): manufacturing process (e.g. mixing times, drying temperatures) equipment (e.g. addition of automatic detection systems) production area and support system changes transfer of processes to another site unexpected changes (e.g. those observed during self-inspection or during routine analysis of process trend data) Change control 8.1 Products manufactured by processes that have been subjected to changes should not be released for sale without full awareness and consideration of the change and its impact on the process validation. 8.2 Changes that are likely to require revalidation may include: — changes in the manufacturing process (e.g. mixing times, drying temperatures); — changes in the equipment (e.g. addition of automatic detection systems); — production area and support system changes (e.g. rearrangement of areas or a new water treatment method); — transfer of processes to another site; and — unexpected changes (e.g. those observed during self-inspection or during routine analysis of process trend data). 8.1 – 8.2

28 World Health Organization

Validation 19 April, 2017 Suspensions Syrups Non sterile products Capsules Creams Ointments Tablets

29 World Health Organization

Validation 19 April, 2017 Non sterile products List some of the key parameters to be considered in the process validation of the dosage forms mentioned 2.4

30 World Health Organization

Validation 19 April, 2017 Prospective validation SUMMARY Ask te participants about principle elements of the topic on the slide

31 World Health Organization

Validation World Health Organization 19 April, 2017 Prospective validation SUMMARY Concurrent validation Ask te participants about principle elements of the topic on the slide

32 World Health Organization

Validation World Health Organization 19 April, 2017 Prospective validation SUMMARY Concurrent validation Retrospective validation Ask te participants about principle elements of the topic on the slide

33 World Health Organization

Validation 19 April, 2017 Prospective validation SUMMARY Concurrent validation Revalidation Retrospective validation Ask te participants about principle elements of the topic on the slide

34 World Health Organization

Validation 19 April, 2017 Prospective validation SUMMARY Concurrent validation Revalidation Retrospective validation Ask te participants about principle elements of the topic on the slide Change control

35 World Health Organization

Validation World Health Organization 19 April, 2017 Group Session You are given a tablet manufacturing flow chart to study List the critical steps that are required to be validated List the critical equipment required to be qualified Identify the variables and construct a table as directed In this group session, (see handout ) you should list the aspects that you will evaluate when assessing the validation for the project that your group had been given. Identify the critical parameters that should have been evaluated by the manufacturer. List the tests to be carried out and comment on the acceptance criteria to be set.

Презентация на тему: Всемирная Организация Здравоохранения

Всемирная Организация Здравоохранения

Всеми рная организа ция здравоохране ния (ВОЗ, англ. World Health Organization, WHO) — специальное агентство Организации Объединённых Наций, состоящее из 193 государств-членов, основная функция которого лежит в решении международных проблем здравоохранения и охране здоровья населения мира. Она была основана в 1948г. со штаб-квартирой в Женеве в Швейцарии. Всеми рная организа ция здравоохране ния (ВОЗ, англ. World Health Organization, WHO) — специальное агентство Организации Объединённых Наций, состоящее из 193 государств-членов, основная функция которого лежит в решении международных проблем здравоохранения и охране здоровья населения мира. Она была основана в 1948г. со штаб-квартирой в Женеве в Швейцарии.

Структура ВОЗ 1. Всемирная ассамблея по здравоохранению. 2. Исполнительный комитет. 3. Секретариат. Всемирная ассамблея здравоохранения является высшим органом ВОЗ, принимающим решения. Основное внимание на ее сессиях, в работе которых участвуют делегации из всех государств-членов ВОЗ, сосредоточено на повестке дня в области здравоохранения, подготовленной Исполнительным комитетом. Основными функциями Ассамблеи являются определение направления деятельности Организации, назначение Генерального директора, наблюдение за финансовой деятельностью Организации, пересмотр и утверждение проекта программного бюджета. Ее ежегодные сессии проводятся в Женеве, Швейцария. Исполнительный комитет состоит из 34 членов, технически квалифицированных в области здравоохранения, каждый из которых назначается государством-членом, избранным для этого Всемирной ассамблеей здравоохранения. Государства-члены избираются сроком на три года. Комитет проводит не менее двух сессий в год; основная сессия обычно проводится в январе, а другая, менее продолжительная сессия, проводится в мае, сразу же после Ассамблеи здравоохранения. Основными функциями Исполнительного комитета является проведение в жизнь решений и политики Ассамблеи здравоохранения, оказание ей консультативной помощи и общее содействие ее работе.

Задачи ВОЗ Предоставление международных рекомендаций в области здравоохранения Установление стандартов здравоохранения Сотрудничество с правительствами стран в области усиления национальных программ здравоохранения Разработка и передача соответствующих технологий, информации и стандартов здравоохранения.

Сферы деятельности ВОЗ Укрепление и совершенствование национальных служб здравоохранения; Предупреждение неинфекционных и инфекционных заболеваний и борьба с ними; Охрана и оздоровление окружающей среды; Охрана здоровья матери и ребёнка; Подготовка медицинских кадров; Развитие медико-биологических исследований; Санитарная статистика.

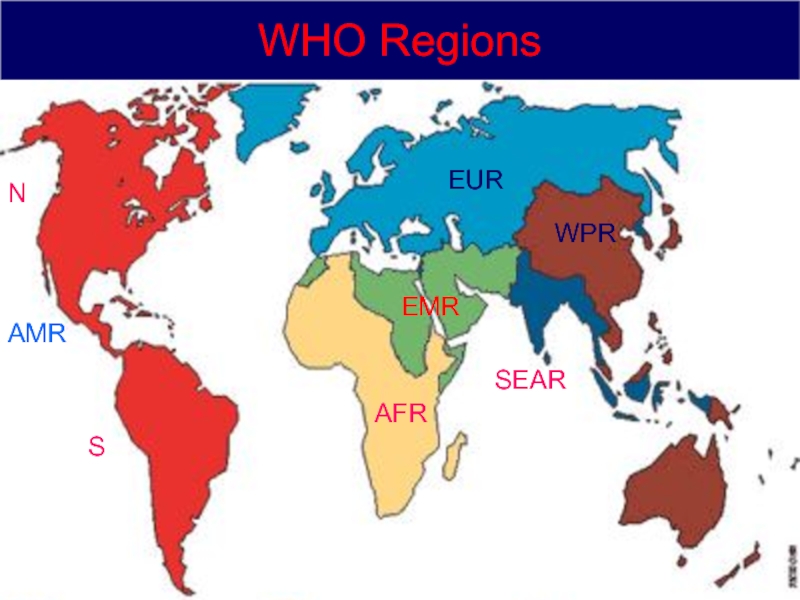

Региональные бюро ВОЗ Европейское — в Копенгагене (Дания), Американское — в Вашингтоне (США), Восточно-Средиземноморское (Средиземноморское) — в Каире (Египет), Юго-Восточной Азии (Азиатское) — в Дели (Индия), Западной части Тихого океана (Тихоокеанское) — в Маниле (Филиппины), стран Африки южнее Сахары (Африканское) — в Браззавиле (Конго).

Работа ВОЗ в настоящее время В настоящее время приоритетными направлениями являются: Развитие систем здравоохранения в странах в соответствии с резолюцией об основных принципах национального здравоохранения (1970), в которой чётко обозначены ответственность государства, средства профилактики, участие населения, использование достижений науки и т. д.; Подготовка и усовершенствование кадров здравоохранения; Развитие первичной медико-санитарной помощи в соответствии с Алма-Атинской декларацией ВОЗ-ЮНИСЕФ (1978); Охрана и укрепление здоровья различных групп населения; Охрана окружающей среды; Борьба с инфекционными и паразитарными болезнями, иммунизация и вакцинация против основных эпидемических заболеваний; Охрана и укрепление психического здоровья; Обеспечение здоровья матери и ребёнка; Информирование по проблемам охраны здоровья; Расширенная программа научных медицинских исследований; Актуальные направления консультативной и технической помощи странам-членам.

World Health Organization

Published bySeamus Gale Modified over 8 years ago

Similar presentations

Presentation on theme: «World Health Organization»— Presentation transcript:

1 World Health Organization

31 March, 2017 Supplementary Training Modules on Good Manufacturing Practice Heating, Ventilation and Air- Conditioning (HVAC) Part 2: HVAC systems and components Section 7

2 World Health Organization

31 March, 2017 HVAC Objectives In the following slides, we will study the components of air- handling systems in order to: Become familiar with the components Know their functions Become aware of possible problems Objectives: For you, as inspectors, to be able to judge whether the air handling systems which you encounter during your factory inspections are adequate or not, it is necessary to know how such systems work, and to be aware of what problems may arise in terms of the components of the system. Therefore, the objectives of this part of module 3 are to study the components of air handling systems in order to: Become familiar with the components Know their functions Become aware of possible problems

3 World Health Organization

HVAC 31 March, 2017 General Design of HVAC is dependent on required degree of air cleanliness Suitable components should be selected including: fans, driers, filters, ducts, grilles, etc. 7. HVAC systems and components Note: The required degree of air cleanliness in most OSD manufacturing facilities can normally be achieved without the use of high-effi ciency particulate air (HEPA) fi lters, provided the air is not recirculated. Many open product zones of OSD form facilities are capable of meeting ISO Class 8, “at-rest” condition, measured against particle sizes of 0.5 μm and 5 μm, but cleanliness may not be classifi ed as such by manufacturers. 7.

4 World Health Organization

31 March, 2017 HVAC Main subsystems + Production Room Exhaust air treatment Central air handling unit Terminal air treatment at production room level Fresh air treatment (make-up air) To understand the air handling systems, it is necessary to know what their components are. A conventional Air Handling System has 4 sub-systems: 1. Air handling of the incoming (fresh) air: elimination of coarse contaminants and protection from frost if necessary. In the case of air re-circulation, the fresh air is also called make-up air. 2. Central air handling unit (AHU), where the air will be conditioned (heated, cooled, humidified or de-humidified and filtered), and where fresh air and re-circulated air, if any, (indicated here by the dotted line) will be mixed. 3. Air handling in the rooms under consideration (pressure differential system, additional filtration, air distribution). 4. Air exhaust system (filtration).

5 World Health Organization

HVAC 31 March, 2017 Components Components in HVAC may include, depending on need: Filters Fans no fan failure; including supply air fans, return air fans, exhaust air fan, dust extract system fans Driers Drying of air with chemical driers, e.g. rotating desiccant wheel Frost coils for preheating air 7.1 General 7.1.1 There should be no failure of a supply air fan, return air fan, exhaust air fan or dust extract system fan. Failure can cause a system imbalance, resulting in a pressure cascade malfunction with a resultant airfl ow reversal. 7.1.2 A schematic diagram of the airfl ow for a typical system serving a low humidity suite is represented in Fig. 23. 7.1.3 Air should be dried with a chemical drier (e.g. a rotating desiccant wheel which is continuously regenerated by means of passing hot air through one segment of the wheel). 7.1.4 The fi gure illustrates the chemical drier handling part of the fresh air/return air mixture on a by-pass fl ow. The location of the chemical drier should be considered in the design phase. Examples of appropriate locations include: — full fl ow of fresh/return air; — partial handling of fresh/return air (by-pass airfl ow); — return air only; — fresh air only; or — pre-cooled air with any of the above alternatives. 7.1.5 Possible additional components that may be required should be considered depending on the climatic conditions and locations. These may include items such as: — frost coils on fresh air inlets in very cold climates to preheat the air; — snow eliminators to prevent snow entering air inlets and blocking airfl ow; — dust eliminators on air inlets in arid and dusty locations; — moisture eliminators in humid areas with high rainfall; and — fresh air pre-cooling coils for very hot or humid climates. 7.1.6 Appropriate alarm systems should be in place to alert personnel if a critical fan fails. 7.1.7 Low-level return or exhaust air grilles are usually preferred. However, where this is not possible, a higher air change rate may be needed to achieve a specifi ed clean area classifi cation, e.g. where ceiling return air grilles are used. 7.1.1 – 7.1.7

6 World Health Organization

HVAC 31 March, 2017 Components Components in HVAC may include, depending on need: Snow eliminators Dust eliminators Moisture eliminators Precooling coils Alarm systems, grilles/diffusers, etc. 7.1.1 – 7.1.7

7 World Health Organization

31 March, 2017 HVAC Filter Silencer Terminal filter Weather louvre Control damper Fan Flow rate controller Humidifier Heating coil Cooling coil with droplet separator Production Room Overview components + Prefilter Exhaust Air Grille Heater Another way to look at an air handling system is to consider the different components and to know their function. Some of the components, particularly the filters, are essential to ensure the quality of the air. We will later consider individual components in detail. Of course, a well-designed air handling system must not only be properly designed, but also properly installed, qualified and maintained (sealed ducts, tight filters). (The trainer should make the audience aware that this slide is just an example, and that all components may not necessarily be present in each system.) Secondary Filter Recirculated air

8 World Health Organization

31 March, 2017 HVAC Components (1) Weather louvre Silencer Flow rate controller Control damper To prevent insects, leaves, dirt and rain from entering To reduce noise caused by air circulation Automated adjustment of volume of air (night and day, pressure control) Fixed adjustment of volume of air A typical HVAC unit consists of a small number of elements only. It is important that these elements are compatible, properly installed, and fulfilling their goal. Whereas a weather louvre and silencer are less critical elements, the components associated with the flow rate control are essential, as they allow adjustment of the air volumes supplied to the rooms, which in turn forms the base for a pressure differential concept: to have an automated or a fixed system is largely a financial matter, but a fixed system is more difficult to set up. Silencer – check internal lining material of silencer as this can cause contamination.

9 World Health Organization

31 March, 2017 HVAC Components (2) Heating unit Cooling unit/ dehumidifier Humidifier Filters Ducts To heat the air to the proper temperature To cool the air to the required temperature or to remove moisture from the air To bring the air to the proper humidity, if too low To eliminate particles of predetermined dimensions and/or microorganisms To transport the air Heating and cooling units (batteries), as well as humidifiers are used to adjust the climate in the room (temperature and humidity). Special de-humidifiers, on a dessiccant base, will be addressed later. Filters are one of the main components, as they determine the size of airborne particles that pass through them, and thus the hygiene class. It is wise to protect the finer filters by pre-filters, thus extending their life cycles, and making them less prone to clogging. Ducts transport the air from the air handling units to and from the rooms. Inspectors must verify that ducts do not have internal insulation as this is a great source of contamination.

10 Control damper for airflow

World Health Organization 31 March, 2017 HVAC Air-handling unit Control damper for airflow Humid room air Air heater Regeneration air Adsorber wheel Dry air Dampers to control pressure differentials are important. They can be automated or fixed. As filters get dirty the system pressure losses increase, and if airflow is not regulated, the flow decreases and pressure differentials change. This could cause flow reversal and cross-contamination. Variable speed drives for fan motors are also commonly used to control airflow. In some cases, it is necessary to have very dry air for galenical reasons in certain rooms (production of effervescent tablets and humidity sensitive products in general). To generate dry air, the air supplied to the production is passed over an adsorbant (silicagel, lithium chloride, etc.) where the humidity is removed from the air. The adsorbant is then re-generated, on a continuous or on a batch-wise base. AHU with fan Variable Speed Controller Filter Pressure Gauges De-humidification

11 Humidifier Silencer Heating and cooling units

World Health Organization 31 March, 2017 HVAC Humidifier Silencer Heating and cooling units This slide shows additional elements of the air handling units. For humidification purposes, especially in clean areas, high purity water should be used, to avoid contamination. The silencer is not important from a GMP point of view, but from an environmental one, as ventilation units can be very noisy. Be sure that the silencers are manufactured of suitable materials as the linings of standard silencers can contaminate air with particulates. Depending on the local legislation, the installation of silencers can be mandatory. The cooling unit is important during the hot season. Be aware that stagnating water (condensed water) can bring bacterial growth, which can contaminate the filters, pass through them (depending on their retention properties) and end up contaminating production areas. It is essential that there is no stagnating water. Cooling coils can be sanitized as well. Do remember that, if filters are not properly maintained, micro-organisms may grow through the filters and be carried towards the production rooms.

13 World Health Organization

31 March, 2017 HVAC HEPA or tertiary filter Primary panel filter This slide shows Primary Panel filters, which are used mainly for lower filtration efficiency or as pre-filters Secondary filters, consisting of mini-pleated media or filter bags, and is used for higher filtration efficiency. HEPA or tertiary filters, usually being the final filter in the system, providing the highest filtration efficiency. Though there is a strong relationship between filter efficiency and cleanroom class, a filter of a high efficiency does not guarantee a high cleanroom class, as many other elements play a role, such as Air flow (how the air is extracted, how well the room is “flushed”) Air speed and number of air changes Positions of air terminals Layout and presence of objects Personnel and clothing Equipment (not all machines are designed to operate in a clean environment!) Proper installation and proper maintenance Secondary filter

14 World Health Organization

31 March, 2017 HVAC This table gives an idea of the efficiency of the filters, calculated across the entire surface (integral value) or in particular spots (local value). Referring to filter ratings by percent efficiency is misleading, as there are so many different types of tests that give different efficiencies for the same filter. This can be very confusing and it is better to refer to the Committee of European Normalisation (EN) test rating i.e. G4, F8, H12, etc.

15 World Health Organization

31 March, 2017 HVAC Positioning of filters (1) AHU mounted final filter Filter in terminal position HEPA Filter + Production Room Production Room In some of the previous slides, we have seen filters both in the central air handling units ( AHU ) and terminally mounted at the production rooms. The filtered air entering a production room can be coming from: an air-handling unit, equipped with pre-filtration and the main (HEPA) filter, but at some distance from that room (left drawing); an air-handling unit, equipped with pre-filtration in the AHU, and an additional filter (HEPA) situated immediately on the air outlet (right drawing). In many cases, there are only filters in the AHU. However, for injectables and sterile forms, it is recommended that they be placed in terminal position, though there is a growing tendency to have terminal filters in all rooms where open products are handled. It is recommended that classes A & B (ISO 4, 5 & 6) have terminal HEPA filters. (Refer to: WHO Export Committee on Specifications for Pharmaceutical Preparations. Thirty-second Report. Geneva, World Health Organization, 1992:59-60 (Technical Report Series, No. 823). Annex 1, 17.3.) If we look at the advantages and disadvantages of terminal or non-terminal filters, we can say that generally speaking, the terminal positioning is more expensive; provides a better protection (any problem arising from the ducts is eliminated); is the preferred method in cleanroom classes with high requirements. HEPA Filter

16 World Health Organization

31 March, 2017 HVAC Positioning of filters (2) Prefilter AHU Main filter Ceiling exhausts Filters can be in different positions, when one considers the central AHU and the rooms. This slide shows an HVAC installation feeding 3 rooms, each one with terminal filters, all filters protected by a remote pre-filter. Room 1 has a turbulent air flow, with low level exhaust. Room 2 has a uni-directional (laminar) air flow over the largest part of the surface, hence the large number of filters. Room 3 has a turbulent air flow, with ceiling exhaust. 2 3 1 Low level exhausts

17 World Health Organization

31 March, 2017 HVAC AHU Prefilter Final filter 2 1 Positioning of filters (3) This slide shows an HVAC installation feeding two rooms, each one without terminal filters, but with remote final filters protected by a pre-filter. Room 1 has a turbulentair flow, with low level exhaust. Room 2 has a turbulent air flow, with ceiling exhaust. If there is no filter in terminal position, it should be ascertained that there are no elements between the main filter and the air outlets which could add contamination. No elements such as fans, heating/cooling batteries, should be situated downstream of the final filter.

18 Swirl Type air diffusors with terminal filters